![]() Siège social : Riom (61 avenue du stade - 63200 RIOM)

Siège social : Riom (61 avenue du stade - 63200 RIOM)

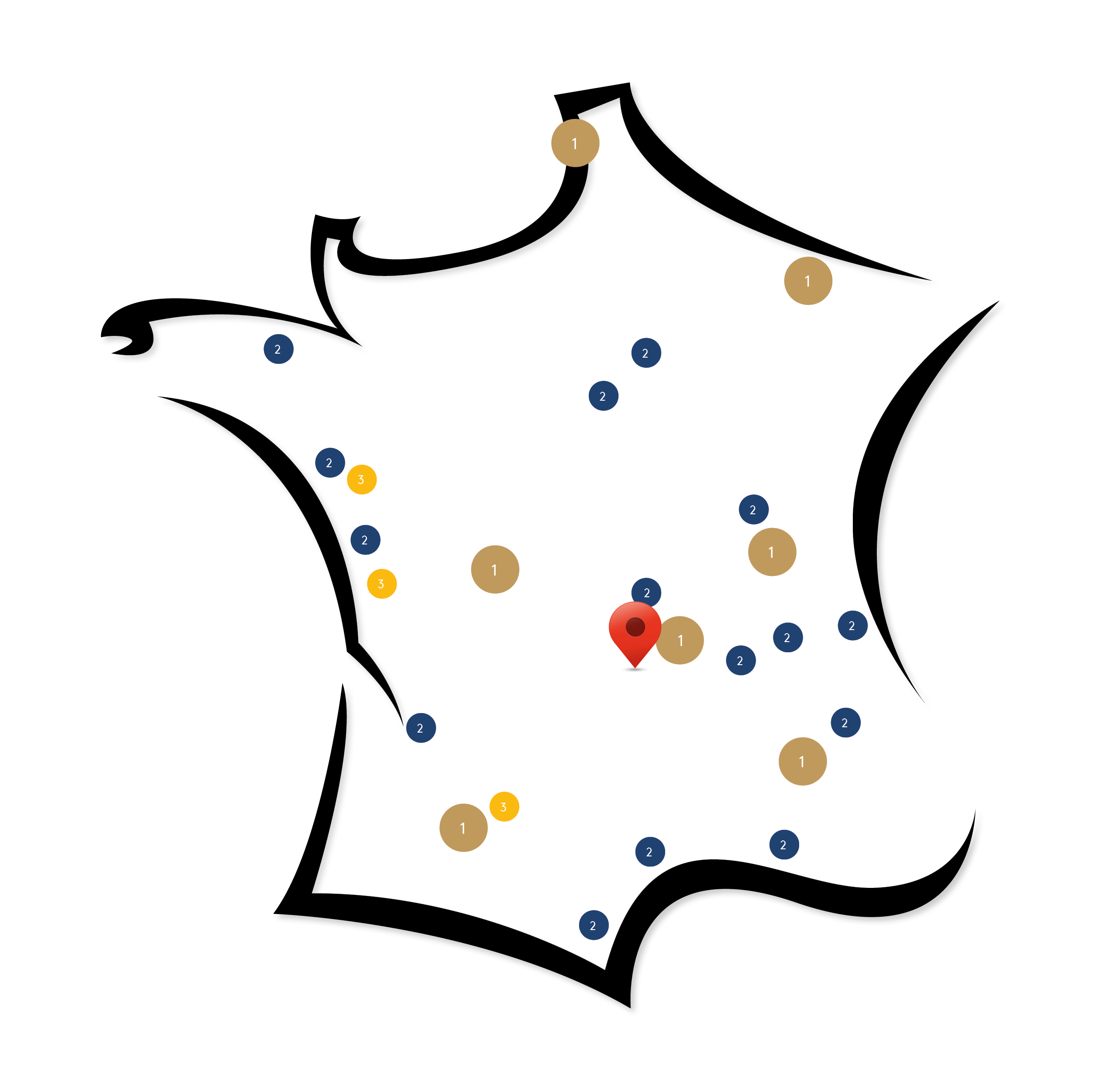

Usines de profilage :

| Bacacier Atlantique T.05 49 42 50 80 |

ZA Val de Bocq 86340 LES ROCHES PREMARIES |

| Bacacier Auvergne T.04 73 64 59 59 |

Route de Chaptuzat 63260 AIGUEPERSE |

| Bacacier Gascogne T.05 62 69 90 06 |

Chemin de Junca 32720 BARCELONNE DU GERS |

| Bacacier Méridional T.04 75 54 81 81 |

ZI Fanjouge 187 chemin du pontet 07700 Bourg-Saint-Andéol |

| Bacacier Nord Flandres T.03 21 89 18 18 |

152 route de Berck 62180 RANG DU FLIERS |

| Bacacier Est T.03 82 44 04 08 |

Avenue Jean Monnet 54920 VILLERS LA MONTAGNE |

Usines de profilage associées :

| Bacacier Est T.03 85 84 48 89 |

Le Colaillot 71600 VITRY EN CHAROLLAIS |

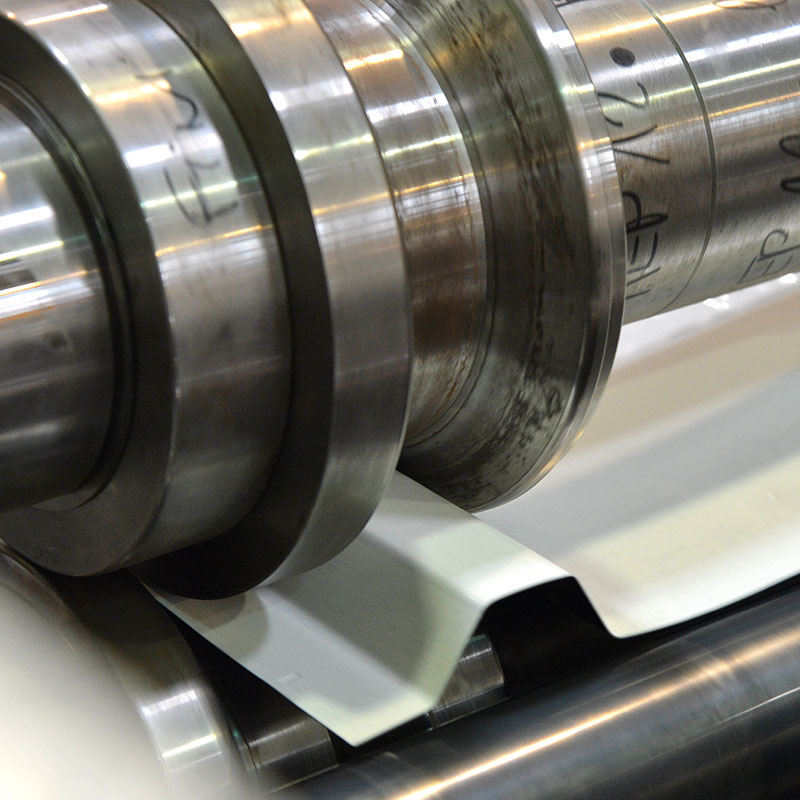

PROFILAGE

Le profilage est une technique de formage à froid par déformation en continu de métal en feuille ou en bobine. Le métal est entrainé par des jeux de galets en acier trempé. Chaque jeu de galets (appelé tête de profilage) effectue une légère déformation du métal. L’ensemble des têtes de profilage compose la profileuse permettant d’obtenir la forme désirée.

EMBOUTISSAGE

L’emboutissage est une technique de fabrication permettant de façonner en creux une tôle d’acier ou d’imprimer une forme en relief sur une tôle. L’emboutissage nécessite l’utilisation d’une presse et d’outillages spécifiques à chaque forme. L’analyse très fine des emboutis est fondamentale pour conserver l’intégrité des revêtements (galvanisation et peinture) qui assurent la durabilité des produits finis.

POINÇONNAGE

La tôle est coincée entre un poinçon et une matrice. La descente du poinçon dans la matrice découpe et/ou déforme la matière comme le ferait une paire de ciseaux. En principe il n’y a pas de limite au poinçonnage, seule la puissance de la machine limite l’épaisseur des matériaux utilisés ainsi que la forme de la découpe. Ce procédé est très précis.

PLIAGE

Le pliage est une technique qui consiste à déformer la matière selon un pli rectiligne grâce à une matrice en forme de V et d’un poinçon.

L’entreprise est ouverte, parce que nous avons souhaité que personne chez Bacacier ne soit inaccessible.

Une démarche de rupture dans l’univers traditionnellement opaque des industriels.

Depuis notre site web www.bacacier.com, nous avons balisé les chemins d’accès, sur notre rubrique «contact».

Vous pouvez poser toutes vos questions sur l’adresse open@bacacier.com, avec un engagement de réponse sous 48h.

Vous pouvez également trouver et joindre par téléphone ou mail, le commercial le plus proche de chez vous.

Enfin, les ingénieurs et le service R&D de Bacacier sont à votre écoute directement pour toutes questions techniques.

Le Service d’Ingénierie et de Développement Produit est le pôle R&D de Bacacier. Il possède une expertise unique de l’enveloppe métallique. Le SIDEP répond à toutes vos problématiques acier et s’engage dans la démarche «open» de Bacacier : services et accessibilité.

Outre l’innovation et l’amélioration produit, le SIDEP développe également des outils et logiciels en ligne destinés à faciliter votre travail au quotidien.

Le SICAP conçoit et développe en interne les outils industriels du Groupe Bacacier. C’est l’assurance d’une autonomie complète, et de la maîtrise de toute la chaine de fabrication.

Le SICAP est également présent dans le process de conception et d’amélioration des produits, entre les ingénieurs du SIDEP et le marketing.

Avec ses multiples usines et implantations en France, Bacacier assure un maillage du territoire et un service de proximité.